Stainless steel objects hardly ever become waste at the end of their useful life.

Today, environmental issues are important criteria for material selection. In evaluating the environmental properties of a material, recycling is a key element. Let us look at the recycling of stainless steel in greater detail. The stainless steel industry has an excellent environmental track record.

We:

Stainless steel objects hardly ever become waste at the end of their useful life. They are systematically separated and recovered to go back into the recycling process. Why is that so?

As well as iron, stainless steel contains other valuable raw materials, especially chromium, nickel and molybdenum, which makes recycling stainless steel economically viable.

It is in fact actively recycled on a large scale around the world.

Stainless steel is not just theoretically recyclable. It is in fact actively recycled on a large scale around the world. Stainless steel recycling is a self-sustaining process. Reprocessing stainless steel is economically viable and technically proven.

Like any metallic material, stainless steel is produced in a melting process.

Production and recycling are not separate steps in the life cycle of the material. They are one and the same process. The most important ingredients for stainless steel production are recycled stainless steel and other steel alloys.

In 2002, about 20 million tons of stainless steel were produced. To make it, about 12 million tons of recycled stainless steel and other recycled ferrous materials were used. Any stainless steel object has an average recycled content of about 60%.

25% old scrap, for example, end-of-life products like tanks or industrial equipment.

25% of material returned from end-of-life products, 35% of material returned from production and manufacturing, and 40% Raw materials, added to the recycling loop.

Stainless steel is made up of:

But if stainless steel has such outstanding recycling properties, why is the recycled content not even higher than 60%?

The selection of stainless steel brings performance and the protection of our natural resources together.

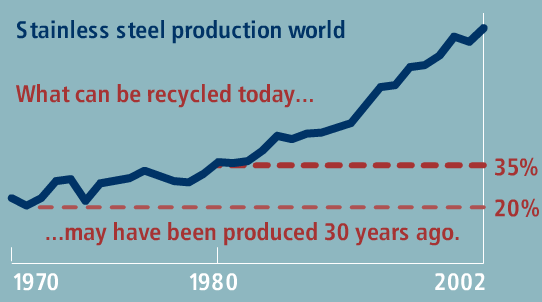

The stainless steel that our industry recycles today may have been out unto the market 20 or 30 years ago. The graph of stainless steel production was far lower than it is today. The long-term average growth rate of stainless steel has been about 5% per annum. Even if 100% of the stainless steel produced was returned, the available material could account for only:

With an average content of 25% of old scrap, stainless steel is close to the theoretical maximum content of material from end-of-life products. The recycled content is only limited by how much stainless steel was put into the recycling loop decades ago.

The unparalleled growth of stainless steel production and use explains why, in 2002, 8 million tons of virgin material had to be put into the recycling loop along with the 12 million tons of recycled material. Stainless steel is not consumed, it remains part of the sustainable closed-loop system. Unlike many other engineering materials, stainless steel is recycled without any degradation!

The selection of stainless steel brings performance and the protection of our natural resources together.